-

WhatsApp / Mob : +86 156 5177 2521

-

Email : mrwin@cnbangwin.com

WhatsApp / Mob : +86 156 5177 2521

Email : mrwin@cnbangwin.com

Hydrogen Generator: Working Principle, Features, Applications & Advantages

Oct 11 , 20251. Introduction

2. What Is a Hydrogen Generator?

3. Working Principle

4. Key Features

5. Technical Specifications

6. Advantages

7. Industrial Applications

8. Frequently Asked Questions (FAQ)

9. Conclusion

10. Meta Description & Focus Keyphrase

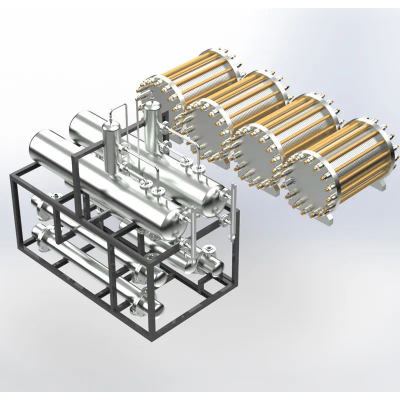

Hydrogen Generator is a modern high-tech system for on-site production of industrial gas.

It supplies hydrogen directly from water or hydrocarbons in a safe and reliable way — serving as a source of high-purity gaseous hydrogen.

Ideal for multiple industrial and energy uses — metal processing, electronics, fuel cells, laboratories — hydrogen generation enables safe and cost-efficient production or testing with minimal environmental impact.

Local hydrogen production is an alternative to compressed cylinders, reducing transportation risks, supply costs, and ensuring continuous operation.

A hydrogen generator is a device that produces pure hydrogen gas on-site.

It works by either electrolysis (breaking down water) or reforming hydrocarbon fuels to separate the hydrogen element.

Hydrogen generators can be fully automated and are designed for high purity and continuous production — to be directly fed into industrial equipment, plants, or research facilities.

The two primary types of hydrogen generators are:

l Electrolysis Hydrogen Generator – Decomposes water into hydrogen and oxygen by electrolysis, powered by electricity.

l PSA (Pressure Swing Adsorption) Hydrogen Generator – Separates hydrogen from a gas mixture with PSA technology.

1. Electrolysis Type

Water supply connected to the electrolyzer. Electric current flows through the electrodes, electrolyzing the water to produce hydrogen and oxygen.Hydrogen gas is directed to storage or the point of use for further purification.

Reaction:

2H₂O → 2H₂ + O₂

2. PSA Type Feed gas, such as reformate or syngas, enters an adsorption column.

CO₂, CH₄, CO, and N₂ are adsorbed while H₂ passes through to the delivery point.

Adsorption and regeneration cycles are alternated to supply a continuous hydrogen flow.

|

Parameter |

Specification |

|

Hydrogen Purity |

99.9% – 99.999% |

|

Production Capacity |

1 Nm³/h – 500 Nm³/h (customized) |

|

Pressure Range |

0.1 – 3.0 MPa |

|

Dew Point |

≤ -60°C |

|

Power Supply |

220V / 380V / 440V |

|

Cooling Type |

Air-cooled / Water-cooled |

|

Control System |

PLC automatic control |

l Gas purity up to 99.999%

l Compact and modular design for easy installation

l Automatic control system with digital display and monitoring

l Low operating cost and minimal maintenance

l Safe design with pressure protection, leak detection, and alarms

l Energy-efficient with low power consumption for continuous operation 24/7

l Immediate Hydrogen Supply – No need to store gas cylinders.

l Reduced Operating Costs – Eliminates gas delivery and refilling expenses.

l Safer – Integrated alarm and shutdown functions.

l Environmentally Friendly – Zero emissions from operation.

l Long Lifespan – Designed for continuous duty in industrial applications.

l Tailored Solution – Capacity, purity, and controls can be customized.

l Metallurgy: annealing, reduction.

l Electronics industry: semiconductor manufacturing.

l Chemical industry: hydrogenation, synthesis.

l Power Plants: generator cooling, protective gas.

l Fuel cells: energy generation, testing.

l Glass industry: float glass, coating production.

A1: Purity is up to 99.999% for electrolysis or PSA hydrogen generators.

A2: Use deionized or distilled water for best performance and longevity.

A3: No need to store or transport high-pressure hydrogen cylinders.

A4: Yes, it is designed for non-stop industrial operation.

A5: Customization options include capacity, purity, and controls.

Hydrogen generators are a green and future-oriented technology for the local production of industrial gas.Ideal for research, energy, industry and the environment, it supplies the user with a high-purity hydrogen source with immediate delivery and automated operation.

Compact, efficient, and reliable electrolysis or PSA systems deliver the perfect sustainable solution for hydrogen supply — minimizing energy use, operating costs and carbon footprint. A hydrogen generator is one of the critical technologies for clean energy and innovation.